Savory Popcorn Production line 100 kg/h. Project in Uruguay.

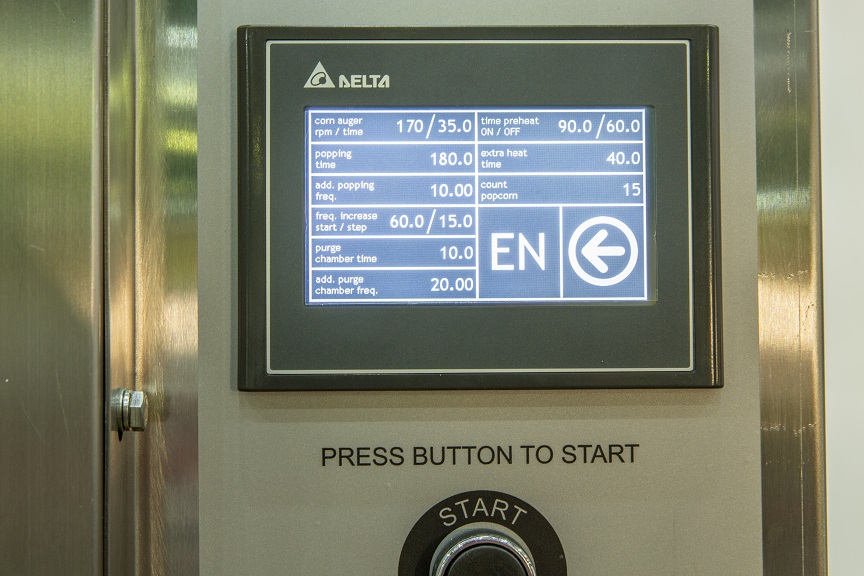

This popcorn production line includes one Grand Robopop 220 machine, with productivity up to 100kg/h of raw corn.

Each popcorn kernel contain up to 13% of moisture, thanks to this moisture inside kernel corn pops when heated. So corn looses its moisture and weight. Total output of popped corn will be approximatelly 80kg/h, depending on corn quality. When you add oil and salt or other savory seadoning on popcorn, weight adds up.

After popping popcorn goes to sieving drum to separate popcorn from unpopped kernels, husk etc. From sieving drum popcorn goes to Collecting Bin. Collecting Bin has popcorn level sencor. From popcorn Collecting Bin through vibrating feeder popcorn goes to Coating Drum with capacity up to 100 kg/h.

Oil is mixed with salt or other savory seasoning in the oil tanks. Oil tanks have volume of 70L each. Oil mix in the tanks is heated up to 60C and constantly agitated.

From Oil Station the mixture is supplied to coating drum, there it is upplied on popcorn.

It is possible to add one more Grand Robopop 220 popper and duble productivity of the line.